How to Use a Plate Compactor | An Elaborate Guide By Expert

Articles, products, and services offered on this site are for informational purposes only. We are part of the Amazon Services LLC Associates Program, an affiliate advertising program. Amazon.com is compensated for sales resulting from links on our website.

Please review our disclaimer before acting based on anything you read or see.

A plate compactor is a powerful tool that any contractor or DIY enthusiast should have in their arsenal.

Its primary purpose is to compress the soil, gravel, and asphalt in preparation for construction work.

But using a plate compactor is more complex than just turning it on and pushing it forward. Specific steps must be taken to ensure the compactor is used correctly and efficiently:

- Identify the Components of a Plate Compactor

- Prepare the Worksite for Plate Compactor Usage

- Select Proper Plate Compactor Settings

- Inspect the Plate Compactor before Use

- Demonstrate Proper Plate Compactor Operation

- Positioning and Leveling the Plate Compactor

- Clean the Plate Compactor

- Maintaining the Plate Compactor

- Store the Plate Compactor

We’ll cover the safety precautions that should be taken before operating the machine, such as wearing the proper safety gear and checking the compactor’s equipment for any defects.

We will also provide tips on preparing the surface you will be compacting and how to operate the compactor to minimize the risk of damaging the surface.

By the end of the blog post, you will have all the information you need to safely and effectively use a plate.

How To Use a Plate Compactor

1. Identify the Components of a Plate Compactor

To effectively use a plate compactor, it’s essential first to identify the components that make up the equipment.

A plate compactor comprises several elements, including the base, the engine, the water tank, the plate, and the handlebars.

The base is part of the machine that allows it to move forward and backward while compacting the surface.

The engine is responsible for powering the machine to enable it to function effectively. The water tank is an essential component used to wet the plate to prevent it from sticking to the surface being compacted.

The plate is part of the machine that directly touches the surface and delivers the compaction force. Lastly, the handlebars are used to steer and control the movement of the machine.

2. Prepare the Worksite for Plate Compactor Usage

Before operating a plate compactor, it is important to prepare the worksite properly to ensure safety and effective compaction.

First, clear the area of all debris, including rocks, roots, and other materials that may interfere with the compaction process. Ensure that the surface is level and uniform to provide the best results.

It is important to mark any utility lines or other hazards that may be present to avoid damage or injury during the compaction process.

Additionally, make sure that the plate compactor is placed on a flat surface with enough clearance to allow for movement during operation.

Taking these steps to prepare the worksite properly will help ensure the efficient and safe use of the plate compactor.

3. Select Proper Plate Compactor Settings

A plate compactor is a powerful tool for compacting soil, gravel, and other materials. It is widely used in construction, landscaping, and road maintenance.

However, using the right settings when operating a plate compactor is crucial to ensure the best results. One of the key aspects of using a plate compactor is to select the proper locations.

A plate compactor has various settings that can be adjusted to achieve the desired results.

Depending on the material being compacted and the conditions of the job site, certain settings will be more effective than others.

In this document, we will discuss the steps you need to take to select the proper settings for your plate compactor to ensure it operates efficiently and effectively.

4. Inspect the Plate Compactor before Use

Before using the plate compactor, it is crucial to inspect it thoroughly to ensure it is safe.

Firstly, check the fuel level and add fuel if required. Check the oil and ensure it is at the proper levels.

Inspect the air filter, ensure it is clean, and replace it if it is dirty. Check the spark plug and ensure it is working correctly.

Check the belts and ensure they are at the proper tension. Inspect the plate and its edges and ensure they are in good condition.

Ensure the throttle and compression switches are functioning correctly. Inspect the bottom plate, secure the bolts, and ensure they are tight.

In all, carry out a complete visual inspection of the plate compactor and address any issues before proceeding with any construction task.

5. Demonstrate Proper Plate Compactor Operation

When using a plate compactor, knowing how to operate it correctly is essential to ensure maximum effectiveness and safety.

One critical aspect of using a plate compactor is understanding proper operation techniques.

It includes knowing how to start and stop the machine, adjusting its speed and direction, and managing any unexpected issues during operation.

Demonstrating proper plate compactor operation involves following a few simple steps.

Begin by inspecting the machine to ensure it’s in good working condition and all safety features are in place. Next, start the engine and allow it to warm up before engaging the compactor.

Once the machine is ready, position yourself behind the handle and slowly move forward, keeping an eye on any obstacles or areas that may require more attention. Lastly, ensure the engine and compactor are shut off properly and safely store the machine when finished.

6. Positioning and Leveling the Plate Compactor

Before using a plate compactor, it is important to properly position and level the equipment to ensure it functions effectively and safely.

Start by selecting a solid and level workspace, free of obstacles or debris. Ensure the plate compactor is level by adjusting the handlebar angle until the base plate is flat.

Next, prepare the surface you wish to compact by clearing any loose debris, such as rocks, sticks, or dirt. Position the plate compactor at the starting point of the surface compact and lower the plate onto the ground.

Finally, ensure that the compactor is facing in the direction of travel and secure the safety throttle in the “kill” position until you are ready to start the engine.

Following these simple steps, you can effectively and safely use a plate compactor to achieve optimum compaction results.

7. Clean the Plate Compactor

When working with a plate compactor, keeping it clean and well-maintained is essential. A dirty plate compactor can compromise its performance and increase the risk of damage to the machine. Therefore, before using the plate compactor, it is critical to clean it thoroughly.

Here are the steps to clean a plate compactor effectively:

- Please turn off the plate compactor and disconnect it from the power source.

- Remove all the debris and dirt from the plate and surrounding areas using a stiff-bristled brush.

- Use a pressure washer to remove dirt and debris from the plate compactor. Do not direct the water stream into sensitive parts like bearings or electrical components.

- Check the plate for any stubborn stuck-on dirt, rust, or corrosion.

- Use a rust remover or grinder to eliminate any hard-to-remove rust.

- Wipe the entire machine with a dry cloth to remove all moisture.

- Finally, lubricate any moving parts that require greasing before use.

Following these steps before each use will help ensure that your plate compactor operates correctly and reliably.

8. Maintaining the Plate Compactor

Maintaining the Plate Compactor is a crucial step in ensuring the longevity and efficient functioning of your plate compactor. Before each use:

- Conduct a pre-operation inspection of the machine, inspecting for any damages, leaks, or cracks in the rubber mat or baseplate.

- Clean it of any dirt or debris that might have accumulated around the engine and air filter compartments.

- Check the engine oil and replace it when required per the manufacturer’s recommendations.

- Keep the fuel tank clean and filled with fresh fuel.

- Inspect the spark plug for any fouling signs and replace it if necessary.

- Ensure the air filter is clean and replace it if dirty; change the oil regularly and lubricate the machine per the manufacturer’s instructions.

It is important to follow the recommended maintenance schedule outlined in the user manual to ensure optimal performance and longevity of the Plate Compactor.

9. Store the Plate Compactor

As DIYers, knowing how to properly store your tools and equipment after using them is important. One example is a plate compactor, which can be a valuable investment in home projects.

Once you’re finished using your plate compactor, you need to store it properly to ensure it will be ready for use in the future. Here are some steps and tips on how to store the plate compactor:

- Clean the compactor: Before storing the plate compactor, clean it thoroughly to remove any dirt, debris, or excess material.

- Inspect the compactor: Check for any signs of damage or wear and tear on the compactor. If you notice any damage, make repairs before storing.

- Remove fuel: Drain the motor of any fuel and dispose of it properly.

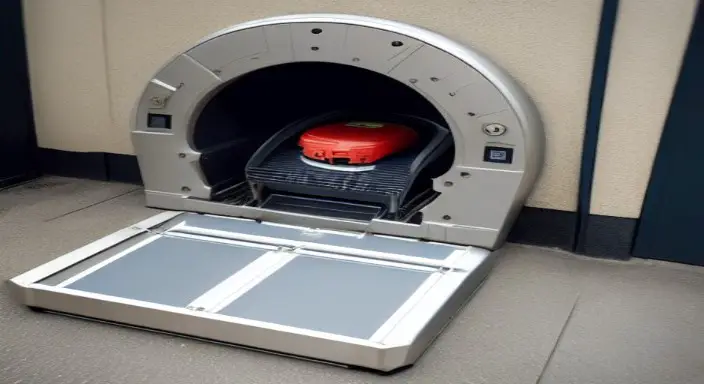

- Store in a dry, covered area: Keep the plate compactor in a dry area to prevent rust and damage. Store it in its original box to protect it from dust and debris.

- Lubricate: Depending on the length of storage, it may be a good idea to lubricate all moving parts to prevent rusting and ensure that they remain in working condition.

10. Clean the plate compactor and store it in a dry, secure place until the next use.

Proper maintenance and storage of a plate compactor are crucial to ensuring optimal performance and longevity.

After completing your project, or if you expect a prolonged period of non-use, the first step is to clean the plate compactor thoroughly. Start by shutting down the engine and disconnecting the spark plug wire.

Then, use a wire brush to remove debris or dirt from the plate and engine components. Next, use a damp cloth to wipe the entire machine down and ensure all parts are free of dirt and moisture.

Once cleaned, allow the machine to dry completely before storing it in a dry and secure location.

Store the compactor in a covered area away from direct sunlight, precipitation, and extreme temperatures to prevent rust or damage.

Proper storage of your plate compactor is essential to ensure its durability and reliable performance for your next project.

My Opinion

In conclusion, using a plate compactor is a relatively easy process that can save time and yield great results when compacting soil, asphalt, or other materials.

Remember to prepare the area you want to compact thoroughly, ensure safety by wearing appropriate gear, and strictly follow the manufacturer’s guidelines for the maintenance and use of the plate compactor.

These tips allow you to use your plate compactor for all your construction or landscaping needs.

Comments are closed.