Cement Concrete Calculator | Get the Amount of Cement Required

Articles, products, and services offered on this site are for informational purposes only. We are part of the Amazon Services LLC Associates Program, an affiliate advertising program. Amazon.com is compensated for sales resulting from links on our website.

Please review our disclaimer before acting based on anything you read or see.

Concrete, formed of cement, and water, is a composite material in which different inert material particles, such as sand and stone ballast, are tightly bound together after solidification. The “aggregate” is an inert substance of various sizes, from fine sand to pebbles, stone ballast, or brick ballast. Usually, this calls for accurate computation. Thus, we have made this post on Cement Concrete Calculator to aid you.

Additionally, cement concrete is a very adaptable building material used to build everything from little cottages to enormous dams and bridges. Compressed cement concrete is fairly strong but not so much in tension. Steel bars reinforcement is included in the concrete to make up for this concrete flaw.

Therefore, the concrete is referred to as reinforced concrete. Here, the cement concrete calculator is also required. Follow along as we go into more detail about this below.

What is Cement Concrete?

Concrete is a mixture that combines binder (cement or lime), aggregate, liquid, admixtures, etc., in a certain ratio to produce an artificial stone-like mass. The mixing ratios determine the strength and quality.

The following equation may be used to represent the formula for making concrete from its constituent parts:

Binder, fine and coarse aggregate, water, and a mixture.

How to Calculate Cement Concrete

You can Calculate Cement Concrete through the following steps:

- Choose the concrete component you wish to pour first, such as a beam, slab, column, set of stairs, wall, or set of steps.

- Calculate the concrete structure’s length, breadth, and depth in feet or inches (US units) or centimeters (metric units), or meters (US units).

- Convert all three dimensions to feet (in US units) or meters (in SI units).

- Enter each dimension into the cement calculator above.

- After that, the concrete’s volume is calculated in cubic meters or cubic feet, depending on your unit.

- To convert cubic feet to cubic yards, multiply by 0.037. This will give you cubic yards.

Cement Concrete Calculator

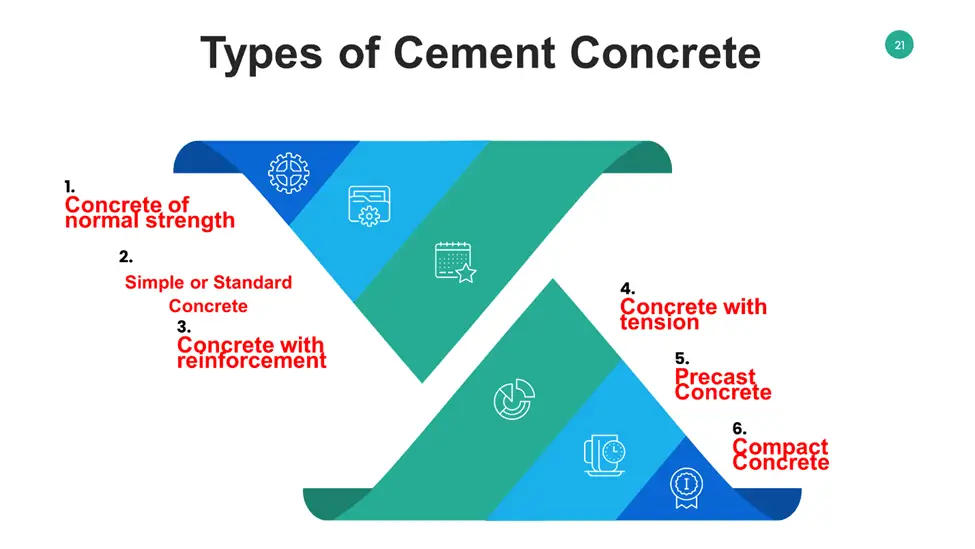

Types of Cement Concrete

There are several varieties of cement concrete, some of which have similar uses. It depends on the objective you want to attain. To complete the work, choose the right kind of concrete. A few of them are:

Concrete of normal strength

This concrete uses a 1:2:4 ratio to blend its three main components—concrete, sand, and aggregate. This results in the concrete of average strength. The concrete might set anywhere from 30 to 90 minutes, depending on the quality of the cement and local weather conditions.

It is often utilized when pavement or a structure doesn’t need high tensile strength. Due to its poor ability to endure the stresses brought on by wind loads or vibrations, it is unsuitable for many other buildings.

Simple or Standard Concrete

This concrete has a 1:2:4 mix pattern, with cement, sand, and aggregates as its main constituents. Where tensile strength isn’t a big concern, you may use it to produce pavement or structures. It has the same problems as concrete of standard strength because it isn’t highly resilient to vibrations or wind loads. Dam building also makes use of plain or standard concrete. The endurance rating of this particular concrete is excellent.

Concrete with reinforcement

This type of concrete is often used in industrial and residential construction nowadays. Wires, metal rods, or wires are put into the concrete before it cures to boost its strength. These items are also referred to as rebar. Eventually, fibers were used to reinforce this concrete.

These anchors withstand tensile stresses, while the cement helps withstand compression pressures. Due to their strong connection, the two materials are resistant to varied applied loads. In essence, they combine to form a single structural element.

Concrete with tension

Many substantial concrete projects employ pre-stressed concrete modules. The creation of pre-stressed concrete involves a special technique. Similar to reinforced concrete, it features bars or tendons. However, these bars or ligaments are stressed before the concrete is placed.

Those bars are placed at the ends of the supporting structure once the cement has been prepared and poured. When the concrete solidifies, this unit is squeezed.

This technique increases the bottom part of the unit’s resistance to tensile forces. But it requires substantial equipment and skilled labor. On-site fabrication and assembly are common for pre-stressed components. Pre-stressing concrete is used in the building of bridges, severely loaded buildings, and long-span rooftops.

Precast Concrete

To strict standards, this cement is made and cast at a factory. The pre-cast concrete components are then transported to the site and assembled.

You often see these modules transported to building sites as you pass roadways. Precast concrete is used to create concrete blocks, precast buildings, stair parts, and poles.

The advantage of precast concrete is its ease of installation. Since they are manufactured in a factory, the components are excellent.

Compact Concrete

Lightweight concrete is any material with a hardness of less than 1920 kg/m3. Lightweight concrete is made using lightweight aggregates. Collates are materials that make a certain kind of concrete denser. These organic materials, such as scoria or pumice, are employed as cement. Along with enhanced shale formations and clays, for instance, as well as treated or synthetic materials like silica and perlite. The most important quality of it is how little heat it conducts.

Long-reaching bridge decks and building blocks are often made of lightweight cement. It could also be used to protect steel structures.

This can also be seen in the infographics below.

What is PCC (Plain Cement Concrete)

Simple Cement Concrete or PCC is often referred to as a blend of cement, stone dust, and coarse aggregate without steel. It is an essential part of a structure placed on the earth’s surface during construction projects to prevent the reinforcing of concrete from coming into direct contact with the soil or water.

Commonly, PCC refers to plain cement concrete (a combination of cement sand and gravel in a predetermined proportion). Lean concrete and regular concrete are often used to create PCC.

PCC, or regular concrete, is formed of M10 and M15 grade concrete and has a medium quantity of cement in the mix. Its primary purpose is to serve as bedding for concrete roads and pavement construction. In the concrete grade M15, M stands for mix, and the number 15 represents the compressive strength of a 150 mm cube after 28 days of curing.

Therefore, the hardness of m15 concrete grade is 15N/mm2, and the mix ratio is about 1:2:4, with one component being cement. Sand makes up two parts of the mixture, while aggregate makes up four parts.

Frequently Asked Questions

How much does 1 bag of concrete cover?

Well, it relies on the slab’s thickness. A 50-pound bag of cement would typically cover 1.25 square feet. A 40-pound bag would cover one square foot of concrete. At a slab thickness of 4 inches, one bag or sack of concrete will typically cover 1 to 2 square feet. A bag of concrete weighing 80 pounds would cover a square foot, while a bag weighing 60 pounds would cover a square foot.

How do I calculate how much concrete I need for a slab?

The steps below may be used to determine how much concrete you need for a slab:

- Determine the square footage.

- Add thickness after you have multiplied length by width.

- To determine cubic yards, divide the resultant value by 27.

Is it cheaper to mix concrete yourself?

Making your concrete is one of the least costly methods due to increased living expenses and the cost of building supplies.

How much concrete is in a bag?

The size of the bag will determine this. 40, 60, and 80 lbs. are typical bag weights. Utilize the yields below for each bag size: The yield per 40-pound bag is—011 cubic yards. The yield per 60-pound bag is—017 cubic yards. A bag of 80 pounds produces—022 cubic yards.

How thick should a concrete slab be?

The usual house floor slab thickness is 4 cm of concrete. Five to six inches is recommended if the concrete could sometimes be exposed to heavyweights like trailer homes or garbage trucks. The foundation system must be constructed on the proper ground level by cutting the ground to the required thickness.

How much concrete do I need for a 10×10 slab?

The arithmetic for a compact patio 10′ x 10′ looks like 10 times 10 equals 100 square feet. 100 x.33 = 33 cubic feet; 4 12 =.33. A 10 × 10 slab requires 1.3 cubic yards of material. To account for any slab depth differences and spills, we always add 10%.

How much concrete do I need for a 12×20 slab?

For 12 feet by 20 feet and 4 inches thick slab, you will typically require 2.93 cubic yards, 79.2 cubic feet, or 2.24 m3 of blended concrete.

How much concrete do I need for a 12×12-foot room?

For a 12 by 12-foot space, you will typically require 1.76 cubic yards, 47.52 cubic feet, or 1.35 m3 of premixed masonry 4 inches thick.

Expert Opinion

Concrete is a highly valuable and important building material. A concrete mixture is produced when the correct proportions of cement, coarse aggregate, and water are combined, and the water and cement begin to react to form a solid mass. The concrete’s rock-like bulk becomes harder as a result.

Due consideration should be given to the selection of the elements, their suitable proportioning, the proper mixing of the concrete, and its proper use and curing to get excellent concrete. At this point, the cement concrete calculator will aid you greatly.

Comments are closed.