Removing a screw with no head presents a unique challenge. The screw is nearly impossible to remove without something to grip and turn.

The best way to tackle a stuck screw is to use a pair of pliers, a drill bit, and some lubricant.

When all else fails, consult a professional to help remove the screw and prevent further damage.

So, we’ll walk you through each step with detailed instructions and helpful tips so you can get the job done with minimal difficulty.

Whether a beginner DIYer or a seasoned professional, you’ll find helpful information to help you confidently tackle your project.

So, let’s explore the best ways to remove a screw with no head.

How to Remove a Screw with no Head

Step 1: Identity which type of screwdriver to use.

Step 1 is to identify which type of screwdriver to use. To do this, you must first identify the type of screw you are dealing with.

Standard screws include flathead, Phillips head, Torx, and hex screws. Once you have determined the type of screw, you must select the head size.

Typical sizes range from 0 to 8. With this information, you can now choose the right type of screwdriver. For example, if you have a Phillips head screw, you should use a Phillips head screwdriver.

Step 2: Apply pressure on the screw head with a hammer.

Once you have successfully driven a nail into the head of the screw, it is time to apply pressure.

Place the head of the hammer on the nail and hit it with your other hand.

It does allow you to exert more force on the screw head, enabling you to loosen the screw. Make sure to hit the nail evenly and with enough power.

Too much force could cause the nail to slip, damaging the screw head further.

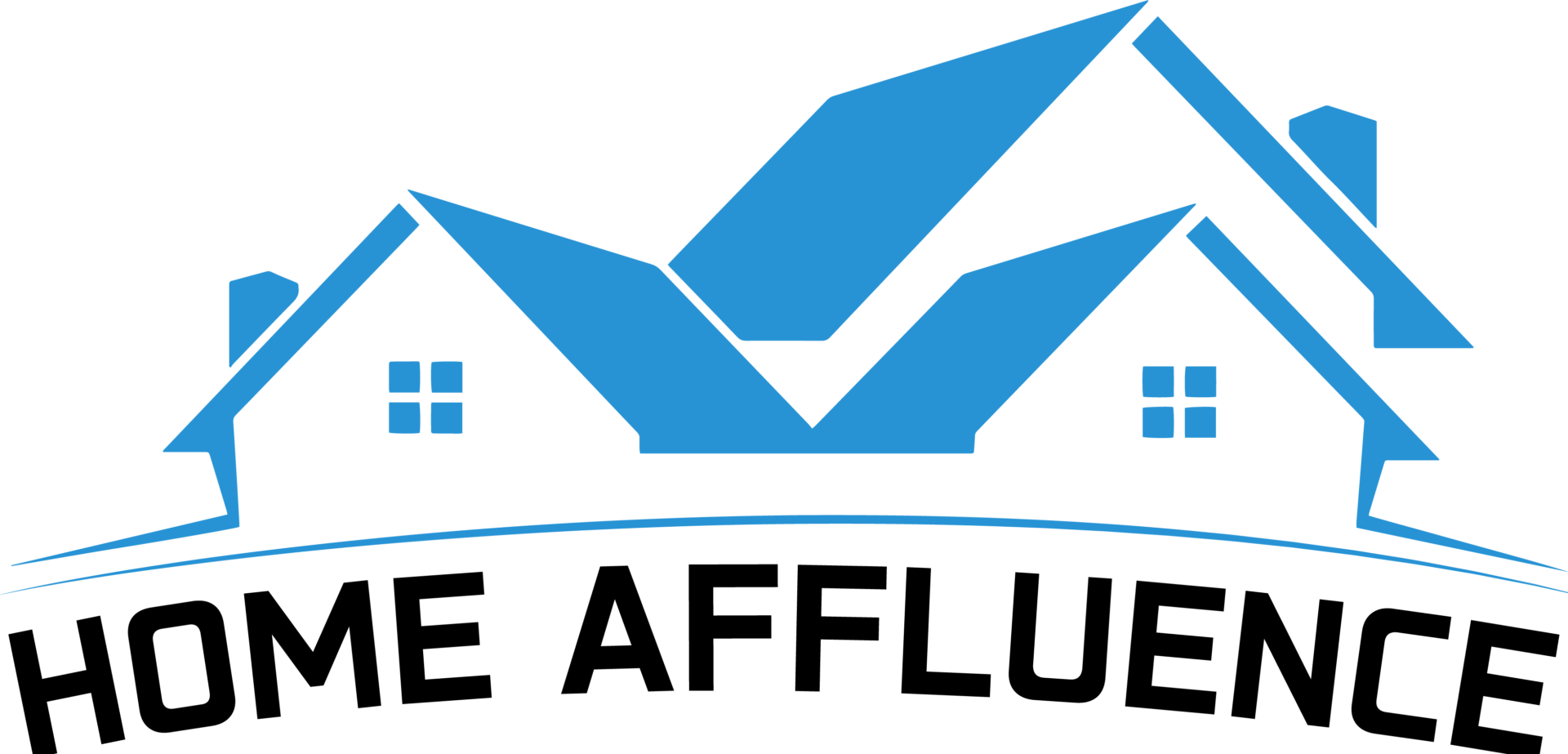

Step 3: Drill a hole where the screw is located.

Once you have determined the exact location of the screw with no head, it is time to drill a hole.

To do this, grab an appropriate-sized drill bit and insert it into your drill.

Ensure the drill is in the right setting, as the wrong environment can cause the drill bit to break. Once the drill bit is in, slowly begin drilling a hole where the screw is located.

Be sure to keep the drill steady and apply even pressure throughout. Stop drilling once the drill bit has gone through the screw.

Step 4: Use an extractor to remove the screw from the hole.

Step 4 is the most critical part of removing the screw with no head. You should use an extractor to remove the screw from the hole.

A screw extractor is a tool with a reverse-threaded bit designed to grip the broken screw and twist it out of the hole.

To use it, insert the extractor bit into the headless hole and turn it counterclockwise.

It does cause the extractor to bite into the screw and unscrew it. Be sure to turn slowly and steadily so you don’t strip the screw or damage the surrounding material.

With some patience, the screw should eventually come loose.

Step 5: Hammer the end of a drill bit into the screw head.

Step 5 is the last in the process, and it is the most difficult. Take a drill bit the same size as the head of the screw and place it on top of the screw.

Then, using a hammer, hit the end of the drill bit with a few hard strikes.

It should be enough to break up the screw’s head, making removing it from the surface easy.

Remember to wear protective gear while doing this step, as the impact of the hammer can be pretty powerful.

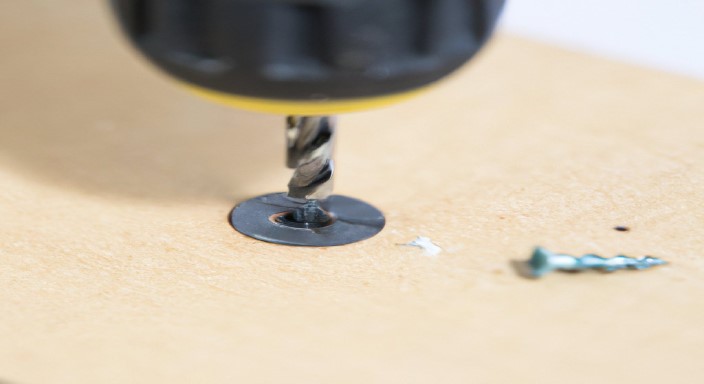

Step 6: Apply heat to soften and expand the metal around the head.

Apply heat to soften and expand the metal around the head. Take a soldering iron or heat gun and apply it to the area around the head of the screw.

Ensure you don’t heat the head directly, as this may cause it to become further embedded in the material.

Allow the heat to warm the metal and let it cool off naturally. It does cause the metal to expand and loosen the head’s grip on the material. With some luck, the head will come off without any trouble.

Step 7: Smash and break off any remaining small parts of the head.

After loosening the screw, you may find that small pieces of the head remain attached to the shank.

If this is the case, gently but firmly use a hammer and a small chisel or flathead screwdriver to smash and break off the remaining pieces. Be sure to wear protective gloves during this process to avoid sharp edges or flying pieces of metal.

Step 8: Sand down the area around the removed screw and replace any damaged pieces as necessary.

After you have successfully removed the damaged screw, it is crucial to make sure the area around the screw does sand down to ensure no sharp edges.

If any pieces of the screw are left behind, make sure to remove them with a pair of tweezers. Once the area sands down, examine the room for any damage and replace any pieces as necessary. Doing this will ensure that the place around the screw is safe and secure.

Step 9: Check for any final remnants and finish by applying paint or a sealant as needed and desired.

Once you prepare the surface and complete the necessary repairs, it is vital to check for any remnants left behind before finishing the job. It may include brushing away any dust or debris accumulated during the process.

After performing a final check, it is time to apply a coat of paint or sealant as needed and desired.

Depending on the surface, this may include an oil-based paint, an alkyd paint, an acrylic enamel, or a polyurethane sealer for added protection.

Regardless of the type of coat chosen, it is crucial to ensure that the surface has been adequately prepped and is free of any contaminants before applying the skin. It does ensure that the coat adheres appropriately and provides the desired protection.

Expert Opinion

Removing a screw with no head can be a tricky process. However, with the proper tools and techniques, removing a stripped or damaged screw is possible without resorting to a drill or screw extractor. With the right approach, you can save a lot of hassle and get the job done quickly and safely.

Fortunately, you can use several clever yet straightforward solutions to remove a screw with no head.

This blog post looked at a few of the most effective methods for removing a screw with no head.

With patience and the right tools, you can successfully remove a screw with no head and complete your project.