PEX has made plumbing easier over the years. The components are easy for plumbers to use and abandon water services immediately for review. Do not wait for the glue joints to set. When you’re done, there are no open flames and no flux to remove from the system. For these reasons, today, we bring you how to connect Pex to a galvanized pipe.

The options for connecting PEX plumbing are numerous, and using PEX to extend an existing galvanized plumbing system is not a problem. Because the flexibility of PEX means there are fewer joints to connect, jobs are completed faster and with less chance of joints leaking. PEX resists heat loss and scale buildup common in metal piping.

PEX also has advantages over other types of materials when it comes to cold. Because of the climate, they can expand rather than crack and break freezing conditions. Besides, this great flexibility makes it possible to reduce the effects of water hammers, the noise of metals, and piping slamming against a home’s structure. New adaptable fittings and brackets make PEX even easier to install.

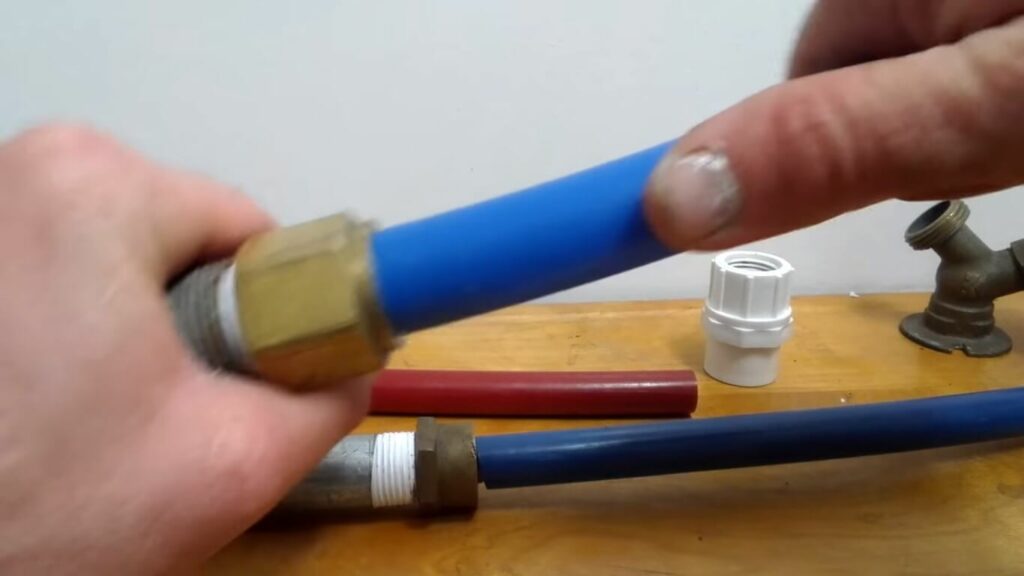

Two methods for connecting PEX do not require a plumber’s license.

- The press-fit method is ideal for quick repairs and requires no special tools other than a pipe cutter.

- You can use a generic crimper for clamp ring connections, available at most plumbing supply stores and stainless steel band clamps. Learn how to prevent water spots on stainless steel sinks.

- When scheduling a PEX plumbing project, it must be remembered that only brass fittings are approved for use subway or under the slab.

What is a Galvanized Pipe?

Galvanized pipes, also called zinc-coated steel pipes, prevent rust and corrosion. Before 1960, galvanized piping was the norm for plumbing systems in homes. Galvanized steel pipe consists of steel pipe coated with zinc. The coating prevents the steel from rusting.

When galvanized steel finds water or the elements, it can be processed into durable plumbing or tubing. Galvanization is the process of coating steel or iron with zinc to prevent rusting. The use of galvanization prevents rusting.

Why Connect PEX to Galvanized Pipe

PEX piping has advantages over galvanized piping, including greater adaptability, a longer lifespan, and a lower initial cost. PEX has many advantages over conventional materials such as copper and PVC.

In contrast to other rigid repiping options, such as copper, you can bend PEX piping and fit it into tight spaces and around tight corners. Because you can mold PEX piping to any size or shape, it eliminates the need to construct entirely new infrastructure for pipes.

PEX piping is a cost-effective and high-quality option for repiping. PEX piping is considerably less expensive than copper piping. Copper generally has higher prices. Due to its compact design, the PEX piping system requires fewer fittings than competing systems. Reducing pipe leakage risk and installation expenses is a win-win situation.

When to Replace a Galvanized Pipe?

Galvanized pipes can last between 60 and 70 years, but this is not always the case. Poor materials or improper galvanization can reduce the lifespan of a pipe from sixty to thirty years. There are some signs that it may be time to replace galvanized pipes.

How to Connect PEX to Galvanized Pipe

A fitting for every situation

A press-fit fitting uses metal barbs to hold the tubing, in this case, PEX and Galvanized, against an O-ring seal.

Fittings are sized according to the outside diameter of the tubing.

A clamp ring connection connects PEX to the existing metal tubing. The PEX tubing is crimped on the male end, and the female end is welded or threaded into the existing tubing. Another procedure is necessary if you have a threadless coupling for galvanized pipe.

Threaded fittings are used to connect different PEX tubing lengths, create a branch line, or add a valve.

Push-in fitting

- Insert the support sleeve. This part prevents the PEX tubing from collapsing and breaking the seal.

- Some suppliers integrate the support sleeve into the fitting.

- You may need the push to connect fittings for galvanized pipe.

Insert PEX tubing

- For a tight seal, make sure the PEX end you want to connect has a straight cut, the tubing is clean, and there are no scratches on the outside.

- Compression fittings are an excellent tool.

Insert Galvanized Tubing

- The tubing end does not require a support sleeve, but like PEX, the outside must be clean and smooth.

- Finally, press the parts to be inserted into the fitting completely to ensure an airtight seal.

- The copper crimping method is usually a bit tedious, but it will be worth it.

Clamp ring connection

- First, attach the adapter to the existing pipe.

- Whether the adapter fitting is threaded on the galvanized pipe or soldered to copper, connect to the existing pipe.

- Then, slide the ring onto the PEX tubing and place the PEX over the adapter’s male end.

- Clamp the ring with a clamp.

- Insert the ring in the middle of the adapter’s male end and tighten it using stainless steel ratchet clamping ring crimping tools. Ratchet clamping tools are often very useful for this.

- Proper placement ensures that the ring compresses the PEX tubing over the ribs for a tight connection.

- You may need to make use of a brass fitting.

In-Line Support

PEX tubing runs with typical PEX to PEX in-line connections should be supported every 3 feet.

However, it is advisable to add a support clip next to the connection at valve joints or bifurcations, where additional weight could put stress on the line. In many instances, you can make use of fit transition adapters. Also, don’t forget to check the tapered plastic compression.

Do I have to Replace my Galvanized Pipes with PEX?

If you have galvanized piping in your home, you should replace it with PEX. PEX tubing is made of cross-linked (X) polyethylene (PE).

It is flexible, durable, and high-density. Reinstalling your indoor plumbing system may seem overwhelming, but PEX is an affordable and convenient option whose benefits far outweigh the hassle:

- They contain no lead components

- Less likely to burst than other pipes

- Do not corrode

- Unaffected by acidic sewage

- Resistant to chlorine and scale.

Do Galvanized Pipes Contain Lead?

While steel pipes do not contain lead, the protective coating is natural zinc.

This type of zinc is considered not very pure and has lead (in addition to other properties), so the coating protects the pipes and extends their service life. It also contains traces of hazardous substances to human health.

As the zinc coating and pipes corrode, lead accumulates and can eventually be released into the water supply.

If your home’s plumbing is nearing the end of its useful life and is severely eroded inside and out, it is a very high lead poisoning. The only way to prevent lead from entering your water stream is to re-pipe your entire house and remove all galvanized pipes.

Non-Galvanized Pipe vs. Galvanized Pipe

| Non-Galvanized | Galvanized |

| It has a component of mild steel used in the production of black iron. The quality of the carbon is deficient. Carbon can increase the corrosion resistance of mild steel. | To counteract this, people can apply zinc protective coating to galvanized pipes. Galvanization, which adds a layer of zinc to the lines, enhances their corrosion resistance, a highly desirable quality. Pipelines can become clogged with mineral deposits; galvanizing them prevents this. |

| The manufacturing process is another significant difference between black iron and galvanized pipes. Either the steel is stretched into a seamless tube, or the edges are forced together and welded to create black iron pipes. | To galvanize pipes, a strip of iron passes through molten zinc. The temperature of the zinc is between 820 and 860 degrees Fahrenheit. Following the completion of the coating process, the newly formed coating is cooled in a quench tank to prevent it from reacting with the atmosphere. |

| Galvanized steel pipes are more brilliant than black iron pipes. The grey hue results from the iron oxide produced during the manufacturing process. | The galvanization process imparts a bright white color to galvanized pipes. Painting over the zinc coating will have a much superior finish. |

| Water has a nasty tendency to corrode black iron pipes rapidly. In this context, the utility of galvanized pipes becomes evident. | Galvanized pipes have been the standard for delivering water to municipal systems for over three decades. Due to its corrosion resistance, you can utilize it in various industrial and outdoor settings. |

| Black iron pipes are more susceptible to rust and corrosion. Water also corrodes this type of pipe. | The coating is more susceptible to corrosion than the underlying steel. This helps the galvanized pipe retain its shape and can add 40 or 50 years to its useful life. |

| Perhaps black iron pipes are less costly than galvanized ones. | If you have a limited budget and durability is not a top priority, black iron pipes may be preferable to galvanized pipes. |

Pros & Cons of using a Galvanized Pipe

| Pros | Cons |

| Rust protection: By introducing an additional barrier through which rust contamination must pass. The iron in steel readily reacts with oxygen and water to form rust. Coating with zinc reduces the likelihood that these elements will cause a reaction. | Corrosion from the inside: The zinc coating on galvanized pipes prevents rusting for a while, but eventually, rust will form. This causes internal corrosion of the pipe, leading to a leak or a complete rupture. |

| Less expensive: Compared to other standard pipe protection methods, galvanization is typically less expensive. This is because galvanization requires considerably less manual labor than the alternatives. | Contamination of Water: Corrosion materials and lead from exposed metal can seep into your water supply if your pipes are galvanized steel. This causes the mineral deposits that line the interior of your tubes to form a plaque. |

| Can survive for more than fifty years in rural areas and more than twenty-five years in the harshest urban and coastal environments. As a result, you will require less maintenance at a time. | A plaque will eventually clog your pipes, preventing water from entering your home. Consequently, the color of the water may alter. |

| It is easy to examine galvanized pipes. Coatings that have been galvanized can be visually inspected and measured in a few straightforward, nondestructive steps. |

Pros & Cons of using PEX with Galvanized Pipe

| Pros | Cons |

| PEX can be bent 90 degrees without the need for fittings because of its flexibility. In contrast, you cannot turn copper, galvanized steel, PVC, and CPVC pipes to get around corners or other obstacles. | Some individuals are concerned that the manufacturing process may contaminate the water source. |

| Cutting pipes and fittings increase the likelihood of leaks occurring behind your walls, which can increase the duration and cost of your project. | Both ultraviolet radiation and chlorine can damage PEX pipes. |

| Since you must also transport hot water through pipes in a plumbing system, the piping material must be suitable for use in extremely hot conditions. | People cannot recycle PEX pipes. |

| Compared to other piping materials, PEX is less expensive than PVC and CPVC but more expensive than copper and galvanized steel. | The calcium in the water steadily builds up on the inside surface of galvanized pipes, reducing water flow until the line is completely clogged. |

| PEX piping is resistant to the corrosive effects of water, in contrast to copper and galvanized steel, which corrodes, rust, and develops mineral deposits after prolonged immersion in liquid. | PEX pipes can be bent and twisted as necessary. They are resistant to extreme temperatures but are not robust enough for use in the wilderness. |

| In the same manner, as PVC and CPVC, PEX degrades when exposed to UV radiation. | PEX pipes also have the disadvantages of being non-recyclable and incompatible with a direct water heater connection. |

| They can be shaped and altered in several ways to fit tight spaces. PEX piping may run the length of a house without needing elbows or other fittings. | Both ultraviolet radiation and chlorine can damage PEX pipes. |

| They provide dependable service for hot and cold water systems and are resistant to heat. | Some individuals are concerned that the manufacturing process may contaminate the water. |

| If you want to upgrade or repipe your property, PEX pipes are a fantastic option. |

Frequently Asked Questions

Can I connect PEX to Galvanized?

Yes, galvanized tubing can be cut with a hacksaw, band saw, or a suitable metal tubing cutter. Assemble a threaded transition fitting that passes from the galvanized pipe/connector to the tubing PEX.

Depending on the type of fittings used in PEX, the dielectric union galvanized to Pex may be required. Attach the PEX tubing to the fitting by a suitable method.

Can Shark bites be used on a galvanized pipe?

Shark Bite push-to-connect fittings are not designed to push on galvanized pipes. To attach your galvanized pipe to Pex, SharkBite makes a threaded transition adapter to press fit. You will need to cut the end of your galvanized pipe square and thread it back on.

How long do Galvanized Pipes last?

Galvanized pipes have a functional life of 20 to 50 years.

If the pipes are used to carry hard water (water with high mineral content), the pipes will corrode faster as magnesium and calcium build up and restrict water flow, shortening the service life.

To ensure long service life, proper metal tubing is necessary.

To extend service life, galvanized pipes must be kept in good condition. Methods include reducing the water pressure to minimize stress on the pipes by installing a pressure reducer and decreasing the hard water’s mineral content by adding a sodium-based softener.

Conclusion

Pex pipe has become a favorite among people over the years. As simple as the task of connecting galvanized pipe to Pex may seem, it is not. It is always important to double-check your crimps with a special pressure test tool.

Never leave the PEX pipe in direct sunlight. It will quickly degenerate the tubing chemicals and ruin the tubing, causing it to fail prematurely. In many instances, excess hot water can be a good thing for your tubing.