Plywood Calculator | Estimate How Much Plywood Sheet Need!

Articles, products, and services offered on this site are for informational purposes only. We are part of the Amazon Services LLC Associates Program, an affiliate advertising program. Amazon.com is compensated for sales resulting from links on our website.

Please review our disclaimer before acting based on anything you read or see.

Plywood is one of the most well-known multi-purpose synthetic wood-based panel materials in building projects. Plywood bonds wood fiber sheets with resin to create a composite material offered in panels. Usually, the face veneers on a plywood panel are of better quality than the core veneers. The increased barrier between the outermost parts, where the strongest bending stresses exist, is the purpose of the core layers, which increases rigidity forces. To prevent waste, this needs an accurate assessment. Thus, we have made this post on the Plywood Calculator to aid you. Come along!

What is Plywood?

Plywood is a wood-based material made by cross-gluing several thin wood strips along the plane. It has a panel-like shape. This makes the action of material properties, such as swelling and shrinking, natural. Plywood is made from veneer sheets with an odd face count.

Plywood is produced in a range of qualities due to its many uses. The two key elements that impact plywood quality are the number of veneer layers and bonding.

Plywood is a different kind of wood flooring sheet material that is made of thin veneer layers or delicate strands of wood that are glued at an angle of 90 degrees. A specific kind of manufactured board resembles a combination of lauan and medium-density fiberboard (MDF). It is a complex compound that uses fiber and glue to bind wood sheets together.

Over the last ten years, plywood has grown in popularity because of its low humidity and versatility in use. The usage of plywood has increased significantly, mostly outdoors.

Plywood Calculator

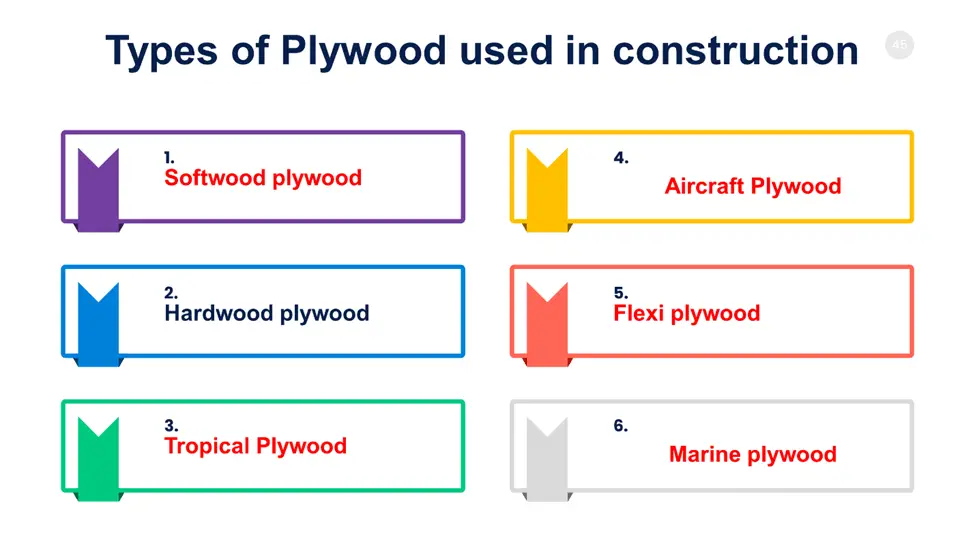

Types of Plywood used in Construction

The following types of plywood are used in buildings:

Softwood plywood

Softwood Even though cedar may sometimes be used to create it, plywood is commonly referred to as spruce-pine-fir, or SPF, since it comprises these three kinds of wood. When made of spruce, the noticeable grains are concealed using a technique that makes the plywood more effective and rigid when creating and shuttering strands.

Hardwood plywood

Hardwood Plywood is produced from angiosperms. This plywood includes stiffness, surface hardness, rigidity, and resistance. With this, heavyweight may be sustained.

Tropical Plywood

This kind of plywood is made by blending several tropical timber types. Although it was formerly only collected in the Asian region, it is now being collected in Africa and America. Tropical pine is well-liked because of its rigidity, uniformity, density, and sturdiness.

Aircraft Plywood

Birch, spruce, and Mahogany woods are employed to manufacture aircraft plywood. Aircraft structural plywood is made from African mahogany. One of the best birch species is the European birch. This species is well known for its power. This kind also consists of mahogany, juniper, and oak, but it has the benefit of withstanding heat.

Flexi plywood

As the name suggests, Flexi Plywood is used to make flexible furniture and structures. The bulk of eighteenth-century furniture featured a curved structure. These are fashioned using Baltic birch (Betula sp).

Marine plywood

A kind of plywood called marine plywood may be used in wet, humid, or damp settings. It may be used for a long time in damp conditions. The core pores in the layers of maritime plywood are too small to allow the board to retain water. It is also fungus resistant.

This can also be seen in the infographics below.

Why you need a Plywood Calculator

You need a plywood calculator since it will make it easier to determine the price and the number of plywood sheets needed for covering walls, floors, or ceilings. Additionally, this is a practical and helpful tool for homeowners and construction workers.

How to Find the Right Amount of plywood

Simply divide the entire square footage by the plywood sheet’s square to get the precise amount of plywood you’ll need.

The dimensions of the area you wish to cover with plywood must next be measured, and the measurement must be rounded to the closest whole number. The length and width variables product may be used to compute the whole area estimate procedure. The numbers from the first step should then be scaled by the area you determined. Divide the computed value of plywood by squaring the area to get the number of plywood sheets. After that, increase the number of sheets by the cost per sheet.

Common Plywood Thickness

The primary PLYWOOD criteria are thickness. When requesting a price or inquiring about plywood, you must explicitly mention what thickness you will purchase or sell. The thickness of plywood varies from 0.4mm to 100mm. However, the typical plywood is 3.2mm x 21mm.

How do I calculate how much plywood I need?

Estimating how many plywood sheets are required for more complex forms is vital. To get a more accurate estimate, follow these instructions.

Measure in the middle of the width of a form like a triangle, trapezoid, or trapezium to get its average length. Add a minimum of four feet for trash after that. Keep in mind that there will be a greater waste with longer cuts.

Find the 25% of the width of a form, such as a circle, pentagon, hexagon, or octagon, and determine the length there. For trash, add at least six feet.

The amount of waste on each plywood run cannot be predicted by a calculation. That depends on how it is laid up and where the plywood stops. There may not always be a waste, as in the case of a 32′ run. You’ll need four sheets. A run that is 31 feet long will likewise need four sheets, with one 12-inch piece remaining.

This waste may have a purpose if the joists or rafters are spaced apart by 12 inches; otherwise, it must be thrown away. As a general guideline, you should increase the number of parts by 10% to account for waste and errors.

How do you calculate the price per square foot for plywood?

The procedures listed below may be used to determine plywood’s cost per square foot:

Step 1: Determine the length and breadth of the area where the plywood will be installed.

This is a crucial step on a floor, roof, wall, or other surfaces. Measure each place individually if you are covering numerous. Round up your measurement to the closest foot in feet.

Step 2: Multiply the length by the width to get the area.

If you measured many places, figure out each space’s area independently and then sum the results. For instance, the space you need to cover to lay plywood sheets on a floor 11 feet by 19 feet is 209 square feet.

Step 3: Round up to the closest foot after dividing the regions from Step 2 by 1.1.

This includes a 10% waste addition. You obtain 229.9 in the second step’s example, which rounds to 230 square feet.

Step 4: To calculate the amount of plywood you’ll need, multiply the number of square feet in your 4- by 8-foot sheet by 32.

The number of sheets you need in the example is 7.2. You must purchase eight sheets unless you may purchase a half sheet.

Step 5: Multiply the sheets by the cost per plywood sheet of the appropriate thickness.

How do you calculate square meters of plywood?

Take the two measurements, length and width, to get the square meters of plywood. Typically, the length and width are measured in feet, and the area of the plywood is calculated as square feet or sqFt.

Area of Plywood = Length x Breadth

Frequently Asked Questions

How much is a 4×8 sheet of plywood?

Based on the size you choose, the price will change. The price range for a 48 sheet with a 1/4-inch thickness is between $6 and $45. A thicker one that is 11/32 inches would cost between $15 and $120 per sheet of the identical size.

What is the cheapest plywood to buy?

Plywood is available in grades A, B, C, and D. The grade indicates the plywood’s face and back veneers’ caliber and looks. D is the least costly, whereas A has the best quality and is the most expensive.

Is OSB stronger than plywood?

Osb has more shear strength than plywood. Shear values are around two times higher across its thickness than plywood. The employment of OSB in links of wooden I-joists is partly due to this. However, effectiveness in shear wall situations is governed by nail-holding capacity.

How many sheets of plywood do I need for a 10×12 shed?

Five 2 x 4 x 10 plates and four 2 x 4 x 12 plates are required. Four 2 x 6 x 12 and three 2 x 6 x 6 headers are needed. Use 10 sheets of external quality plywood 1/2 inch by 4 inches by 8 inches to cover the walls. 230 square feet of your preferred siding are needed for external finishing.

How much does a square foot of plywood cost?

For a 4-by-8-foot panel, the supplies cost between $40 and $50, or about $1.50 per square foot for a 5/8-inch board. Keep in mind that more expensive plywood will be thicker.

Expert Opinion

Plywood is a man-made material valued for its incredible adaptability and may be found in various home furnishings, floors, walls, and doors. Plywood is made up of multiple thin, glued-together layers, is both strong and light is far less expensive than solid wood.

Additionally, plywood provides performance that is better than wood in a few significant respects. Due to its structure, plywood is less susceptible to dampness. Additionally, it withstands variations in humidity and temperature that may sometimes cause natural wood to become stressed to the point of cracking, breaking, or other degradation. Overall, the Plywood Calculator will aid you in effectively using this product.

Comments are closed.