Walls form the division and skeleton of a building, the shell. In addition to sealing the rooms, their main functions are insulation against cold and noise and the ability to support the top’s structural elements. The thickness is determined according to building regulations and building physics for the wall types and the wall lengths. If you have never dealt with this topic before, it can be unclear for you at the beginning of a building design how different thick walls in and around the house should be. If I answer in short how thick should walls be, the maximum recommended thickness for walls up to 70 feet high is 12 inches. When it comes to standard building materials, masonry walls tend to be the thickest add an extra 4 inches for each additional 70 feet in height. Any thickness greater than this, regardless of the material, is excessive.

Read More: How To Build A Concrete Block Retaining Wall

There are already certain standard dimensions for different walls. For example, partition walls have different dimensions than load-bearing walls, outer walls are usually substantial, and various factors also determine the thickness of the masonry. But don’t panic! Below you will find all the answers to the secret of how thick should walls be.

What Determines the Thickness of the Wall?

The enclosing structure is a complex engineering structure with many tasks. In addition to protection from rain, wind, frost, and solar radiation, it perceives the load from ceilings, roofs, and everything on them. Internal walls and partitions divide the space into rooms too. The required wall thickness to support the function depends on the following factors:

The type and properties of the material – strength, thermal conductivity, frost resistance, resistance to various kinds of loads, installation method;

The climatic zone of the building – the minimum and average temperatures during the heating season, the amount of solar radiation, the strength and direction of the winds; The microclimate of the room and the required humidity regime, depending on the purpose – residential, household, heated or cold;

- Seasonality of use – during temporary operation, no energy-saving requirements is imposed on buildings;

- Effective loads – the higher they are, the stronger the wall must be;

The type and number of storeys of the building – at the lower level, the load is much higher than at the upper one; Combinations with external insulation – when using thermal insulation, the calculation is carried out only for strength, which leads to a reduction in the consumption of wall materials;

The nature of the finish – heat-insulating plaster or thermal panels helps retain heat without increasing the walls’ thickness.

Which Masonry Thickness is Common?

There are standardized values for the thickness of walls. You have to differentiate between three types of walls. This includes non-load-bearing partition walls, load-bearing walls, and outer walls.

You should pay attention to the minimum dimensions, especially with load-bearing walls. The construction of outer walls is also of great importance and can get you a little confused at the beginning. So it would help if you differentiated between single and double outer walls. A clinker brick facade made of clinker bricks, for example, represents a double-shell outer wall. In contrast, plastered brickwork made of bricks or aerated concrete is a single-shell outer wall. You should now note that the double-shell outer wall’s total thickness is higher, but this does not apply to the masonry’s components.

Learn To Install A Lintel In An Existing Brick Wall.

How Thick Should Non-Load-Bearing Walls be?

In the case of non-load-bearing masonry, it is usually sufficient to use drywall construction. Otherwise, sand-lime brick walls are suitable as inexpensive masonry partition walls. The standard values of non-load-bearing walls are usually 11.5 cm. However, it is also possible to build them only 5.2 cm or 7.1 cm thick.

How Thick Should Load-Bearing Walls be?

Silicate is often used when laying internal load-bearing walls and partitions because it is much better than ceramic red in terms of sound insulation characteristics.

Its masonry is made in the same way as ordinary clay bricks. The internal partition, which carries an additional load, must be 25 cm thick. Otherwise, it will not withstand the loads. Inter-room partitions, the purpose of which is only to divide the inter-room space, are made in half a brick, and this is enough. The thinnest partitions are 6.5 cm thick. To achieve this thickness, it is enough to lay the brick on the edge. Thin partitions with a length of more than 1.5 m are equipped with reinforced wire.

Learn To Dispose Of Old Bricks.

If such thin internal walls require enhanced sound insulation, then they are trimmed with unique sound-absorbing materials. For this, cork foam sheets are suitable.

To minimize the basement load and reduce the total weight of the entire house, hollow bricks are used for partitions. Also, load-bearing walls are statically more resilient than partition walls and are therefore designed to be stronger.

What are the Usual Dimensions for External Walls?

There are five different standard dimensions for external walls. These are 24 cm, 30 cm. 36.5 cm. 42, 5 cm, and 49 cm. To decide how thick you ultimately build a wall, you should always consider all influencing factors individually.

For external walls, you should also calculate the effect of the thermal insulation. For example, you can intentionally build an aerated concrete wall much stronger to provide adequate insulation. This can save you time and money. Of course, you can still use additional thermal insulation to increase the effect.

How thick should walls made with other materials besides bricks be?

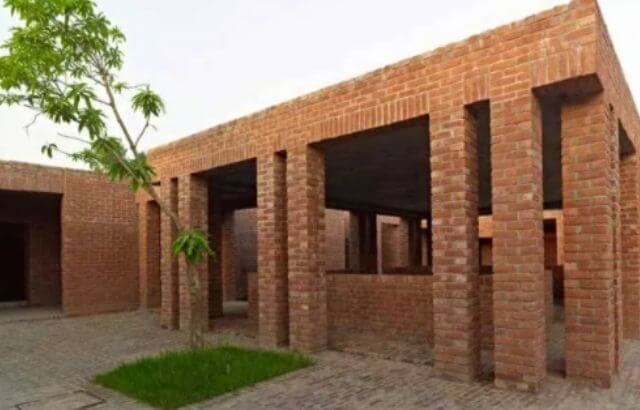

Brick walls are strong; withstand well the load from beams and reinforced concrete floor slabs, suspended equipment. But their thermal conductivity is quite questionable. To this end, walls are currently made with other materials such as:

- Aerated concrete

- Foam block

- Wood

How thick should Aerated Concrete walls be?

Aerated concrete blocks are widely used in the construction of private houses. The high self-supporting capacity of this material allows the construction of houses up to 5 floors. The aerated concrete grade indicates its density – from 300 to 1200 kg / m³. The lower the indicator, the better the thermal insulation properties are, but the lower the material’s strength.

In private construction, up to 3 floors, aerated concrete blocks of class B 2.5 brands D500-900 are used.

Here, the recommended wall thickness for non-residential buildings, summer kitchens, single-story houses in regions with a warm climate is 300 mm. Fences for garages and outbuildings are not standardized for resistance to heat transfer. A wall with a 200-300 mm thickness will fully withstand the load from the roof of a small span.

The outer walls of basements should not be thinner than 300-400 mm. Aerated concrete B 3.5 grade not lower than D600 is usually used too.

How thick should the Walls of the Foam Block be?

Foam concrete is usually used to make foam blocks. They acquire structure during the production process due to additives that provoke the formation of tiny closed pores.

In terms of strength and thermal insulation properties, foam concrete is inferior to aerated concrete. Its thermal conductivity is higher, and its specific gravity is higher. Foam concrete blocks are laid on a cement-sand mortar, leading to uneven heat transfer through the walls and the formation of cold bridges.

Read More: How To Install Door Trim With Uneven Walls

Here, the recommended wall thickness should be 400 mm. In the residential areas, the walls must be insulated. For this, cladding with bricks, expanded polystyrene, or mineral wool is used.

Garages, outbuildings, and premises with seasonal use can be left without insulation. But due to the low frost resistance of the material, the outer surface must be protected with plaster.

How thick should the wooden wall be?

Wooden houses are built from rounded logs, solid or glued beams. Standard sizes of round sawn timber are from 160 to 280 mm with a graduation of 20 mm; the thickness of the lumber profile is 95-275 mm.

- For the construction of houses, pine, spruce, larch, cedar, oak are most often used.

- A wooden house can be built using two technologies:

- From a bar or log up to 165 mm thick with additional insulation;

- From thicker lumber without external or internal thermal insulation.

- In the first case, significant savings are achieved on heating the building in winter; in the second, a comfortable microclimate is achieved by more intensive heating.

Wood is considered a warm material, but according to the thermal conductivity calculation, the wall thickness that meets the energy-saving requirements must be at least 350mm.

How Thick Should Walls Be: FAQs

How thick are walls on a floor plan?

This will be dependent on the method of construction of the wall. The interior walls are usually about 5.5 inches thick, and the exterior walls are about 7.5 inches. If you are drawing a floor plan of an existing house, measure the walls’ thickness on the doors and windows. Also, company standards often set a maximum percentage of minimum yield strength, and in this example, you multiply the company maximum times 42 ksi, not 20 ksi. If your company only allows 20% of minimum yield strength at normal operating pressure, then any value from Eq.

What is the average thickness of an exterior wall?

As earlier highlighted, the average thickness of an exterior wall is between 24 cm and 49 cm.

What is the minimum wall thickness?

The minimum wall thickness is between 24 cm and 26 cm, though this is quite dependent on the materials used in constructing the wall. The riser also resists collapsing with the top 8000 ft (2438 m) of riser empty, even with manufacturing tolerances of 8% on wall thickness. That would mean the process had a 50 percent part yield. Industry constraints permit a thickness variation of 10%. This results in a broad variety of sizes since the entire difference from the thinnest to thickest is up to 20%.

Conclusion

How Thick Should Walls Be? The answer to this question is not quite simple as it seems. On the one hand, the thicker the wall, the better it retains heat. On the other hand, unjustified waste of material leads to financial losses during the construction phase. Improving energy efficiency is also a priority area in the modern economy. The share of heating costs exceeds half of the total building operating costs. This is especially acute when energy prices rise. To prevent heat loss from taking away most of the family budget, you need to determine the house’s walls’ optimal parameters, as highlighted above, before starting construction.